Bewise Inc. www.tool-tool.com Reference source from the internet.

From Wikipedia, the free encyclopedia

|

|

| General |

| Name, Symbol, Number |

silicon, Si, 14 |

| Chemical series |

metalloids |

| Group, Period, Block |

14, 3, p |

| Appearance |

as coarse powder,

dark grey with bluish tinge

|

| Standard atomic weight |

28.0855(3) g·mol−1 |

| Electron configuration |

[Ne] 3s2 3p2 |

| Electrons per shell |

2, 8, 4 |

| Physical properties |

| Phase |

solid |

| Density (near r.t.) |

2.33 g·cm−3 |

| Liquid density at m.p. |

2.57 g·cm−3 |

| Melting point |

1687 K

(1414 °C, 2577 °F) |

| Boiling point |

3538 K

(3265 °C, 5909 °F) |

| Heat of fusion |

50.21 kJ·mol−1 |

| Heat of vaporization |

359 kJ·mol−1 |

| Heat capacity |

(25 °C) 19.789 J·mol−1·K−1 |

Vapor pressure

| P/Pa |

1 |

10 |

100 |

1 k |

10 k |

100 k |

| at T/K |

1908 |

2102 |

2339 |

2636 |

3021 |

3537 |

|

| Atomic properties |

| Crystal structure |

Face-centered cubic |

| Oxidation states |

4

(amphoteric oxide) |

| Electronegativity |

1.90 (Pauling scale) |

Ionization energies

(more) |

1st: 786.5 kJ·mol−1 |

| 2nd: 1577.1 kJ·mol−1 |

| 3rd: 3231.6 kJ·mol−1 |

| Atomic radius |

110 pm |

| Atomic radius (calc.) |

111 pm |

| Covalent radius |

111 pm |

| Van der Waals radius |

210 pm |

| Miscellaneous |

| Magnetic ordering |

nonmagnetic |

| Thermal conductivity |

(300 K) 149 W·m−1·K−1 |

| Thermal expansion |

(25 °C) 2.6 µm·m−1·K−1 |

| Speed of sound (thin rod) |

(20 °C) 8433 m/s |

| Young's modulus |

150 GPa |

| Bulk modulus |

100 GPa |

| Mohs hardness |

6.5 |

| CAS registry number |

7440-21-3 |

| Band gap energy at 300 K |

1.12 eV |

| Selected isotopes |

|

|

| References |

|

|

Silicon (IPA: /ˈsɪlikən/, Latin: silicium) is the chemical element that has the symbol Si and atomic number 14. A tetravalent metalloid, silicon is less reactive than its chemical analog carbon. As the eighth most common element in the universe by mass, silicon occasionally occurs as the pure free element in nature, but is more widely distributed in dusts, planetoids and planets as various forms of silicon dioxide or silicate. On Earth, silicon is the second most abundant element (after oxygen) in the crust, making up 25.7% of the crust by mass.

Silicon has many industrial uses. Elemental silicon is the principal component of most semiconductor devices, most importantly integrated circuits or microchips. Silicon is widely used in semiconductors because it remains a semiconductor at higher temperatures than the semiconductor germanium and because its native oxide is easily grown in a furnace and forms a better semiconductor/dielectric interface than almost all other material combinations.

In the form of silica and silicates, silicon forms useful glasses, cements, and ceramics. It is also a component of silicones, a class-name for various synthetic plastic substances made of silicon, oxygen, carbon, germanium, and hydrogen, often confused with silicon itself.

Silicon is an essential element in biology, although only tiny traces of it appear to be required by animals. It is much more important to the metabolism of plants, particularly many grasses, and silicic acid (a type of silica) forms the basis of the striking array of protective shells of the microscopic diatoms.

[edit] Notable characteristics

Having the same structure to the outer electron orbitals (half filled subshell holding upto eight electrons) as Carbon, the two elements are very similar chemically and both are semiconductors readily either donating or sharing their four outer electrons allowing many different forms of chemical bonding. Pure silicon has a negative temperature coefficient of resistance, since the number of free charge carriers increases with temperature. The electrical resistance of single crystal silicon significantly changes under the application of mechanical stress due to the piezoresistive effect.

In its elemental crystalline form, silicon has a gray color and a metallic luster which increases with the size of the crystal. It is similar to glass in that it is rather strong, very brittle, and prone to chipping. Even though it is a relatively inert element, silicon still reacts with halogens and dilute alkalis, but most acids (except for some hyper-reactive combinations of nitric acid and hydrofluoric acid) do not affect it. Having four bonding electrons however gives it, like carbon, many opportunities to combine with other elements or compounds under the right circumstances.

[edit] Applications

As the second most common element on earth, Silicon is a very useful element that is vital to many human industries, and impacts much of modern life as a principle component in glass, concrete and cements of many kinds. Outside of the many modern world features its construction uses enable, perhaps Silicon's most lifestyle affecting application is its use as the fundamental substrate in manufacturing electronics integrated circuits such as computer chips, and discrete active devices such as power transistors. Further, the element and its compounds find widespread use in explosives and pyrotechnics [1] and further uses in mechanical seals, high temperature silicon based greases, caulking compounds and so forth. It's not much of a stretch to say it might be easier to list applications which Silicon does not affect instead of the broad family of uses it does—and it is certainly fair to say without Silicon's uses, our life would be unrecognizably different if at all possible.

[edit] Alloys

- The largest and biggest application of pure silicon (metallurgical grade silicon) is in aluminum-silicon alloys, often called "light alloys", to produce cast parts, mainly for automotive industry. (This represents about 55% of the world consumption of pure silicon.)

- The second largest application of pure silicon is as a raw material in the production of silicones (about 40% of the world consumption of silicon)

- Pure silicon is also used to produce ultra-pure silicon for electronic and photovoltaic applications:

- Steel and cast iron: Silicon is an important constituent of some steels, and it is used in the production process of cast iron. It is introduced as ferrosilicon or silicocalcium alloys.

[edit] Compounds

- Construction: Silicon dioxide or silica in the form of sand and clay is an important ingredient of concrete and brick and is also used to produce Portland cement.

- Pottery/Enamel is a refractory material used in high-temperature material production and its silicates are used in making enamels and pottery.

- Glass: Silica from sand is a principal component of glass. Glass can be made into a great variety of shapes and with a many different physical properties. Silica is used as a base material to make window glass, containers, insulators, and many other useful objects.

- Abrasives: Silicon carbide is one of the most important abrasives.

- Medical materials: Silicones are flexible compounds containing silicon-oxygen and silicon-carbon bonds; they are widely used in applications such as artificial breast implants and contact lenses. Silicones are also used in many other applications.

- Silly Putty was originally made by adding boric acid to silicone oil. Now name-brand Silly Putty also contains significant amounts of elemental silicon. (Silicon binds to the silicone and allows the material to bounce 20% higher.)

See also Category:Silicon compounds

[edit] History

Silicon was first identified by Jöns Jakob Berzelius in 1787 (as a component of the Latin silex, or silicis (meaning what were more generally termed "the flints" or "Hard Rocks" during the Early Modern era where nowadays as we would say "silica" or "silicates"), and was later mistaken by Humphry Davy in 1800 for a compound. In 1811 Gay-Lussac and Thénard probably prepared impure amorphous silicon through the heating of potassium with silicon tetrafluoride. In 1824, Berzelius prepared amorphous silicon using approximately the same method as Lussac. Berzelius also purified the product by repeatedly washing it.

Because silicon is an important element in semiconductors and high-tech devices, the high-tech region of Silicon Valley, California, is named after this element.

[edit] Occurrence

Measured by mass, silicon makes up 25.7% of the Earth's crust and is the second most abundant element on Earth, after oxygen. Pure silicon crystals are only occasionally found in nature; they can be found as inclusions with gold and in volcanic exhalations. Silicon is usually found in the form of silicon dioxide (also known as silica), and silicate.

Silica occurs in minerals consisting of (practically) pure silicon dioxide in different crystalline forms. Sand, amethyst, agate, quartz, rock crystal, chalcedony, flint, jasper, and opal are some of the forms in which silicon dioxide appears. (They are known as "lithogenic", as opposed to "biogenic", silicas.)

Silicon also occurs as silicates (various minerals containing silicon, oxygen and one or another metal), for example feldspar. These minerals occur in clay, sand and various types of rock such as granite and sandstone. Asbestos, feldspar, clay, hornblende, and mica are a few of the many silicate minerals.

Silicon is a principal component of aerolites, which are a class of meteoroids, and also is a component of tektites, which are a natural form of glass.

See also Category:Silicate minerals

[edit] Production

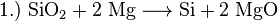

Silicon is commercially prepared by the reaction of high-purity silica with wood, charcoal, and coal, in an electric arc furnace using carbon electrodes. At temperatures over 1900 °C, the carbon reduces the silica to silicon according to the chemical equation

- SiO2 + C → Si + CO2.

Liquid silicon collects in the bottom of the furnace, and is then drained and cooled. The silicon produced via this process is called metallurgical grade silicon and is at least 98% pure. Using this method, silicon carbide, SiC, can form. However, provided the amount of SiO2 is kept high, silicon carbide may be eliminated, as explained by this equation:

- 2 SiC + SiO2 → 3 Si + 2 CO.

In 2005, metallurgical grade silicon cost about $ 0.77 per pound ($1.70/kg).[2]

[edit] Purification

The use of silicon in semiconductor devices demands a much greater purity than afforded by metallurgical grade silicon. Historically, a number of methods have been used to produce high-purity silicon.

[edit] Physical methods

Silicon wafer with mirror finish (NASA)

Early silicon purification techniques were based on the fact that if silicon is melted and re-solidified, the last parts of the mass to solidify contain most of the impurities. The earliest method of silicon purification, first described in 1919 and used on a limited basis to make radar components during World War II, involved crushing metallurgical grade silicon and then partially dissolving the silicon powder in an acid. When crushed, the silicon cracked so that the weaker impurity-rich regions were on the outside of the resulting grains of silicon. As a result, the impurity-rich silicon was the first to be dissolved when treated with acid, leaving behind a more pure product.

In zone melting, also called zone refining, the first silicon purification method to be widely used industrially, rods of metallurgical grade silicon are heated to melt at one end. Then, the heater is slowly moved down the length of the rod, keeping a small length of the rod molten as the silicon cools and re-solidifies behind it. Since most impurities tend to remain in the molten region rather than re-solidify, when the process is complete, most of the impurities in the rod will have been moved into the end that was the last to be melted. This end is then cut off and discarded, and the process repeated if a still higher purity is desired.

[edit] Chemical methods

Today, silicon is instead purified by converting it to a silicon compound that can be more easily purified than silicon itself, and then converting that silicon element back into pure silicon. Trichlorosilane is the silicon compound most commonly used as the intermediate, although silicon tetrachloride and silane are also used. When these gases are blown over silicon at high temperature, they decompose to high-purity silicon.

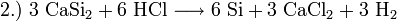

At one time, DuPont produced ultra-pure silicon by reacting silicon tetrachloride with high-purity zinc vapors at 950 °C, producing silicon according to the chemical equation

- SiCl4 + 2 Zn → Si + 2 ZnCl2.

However, this technique was plagued with practical problems (such as the zinc chloride byproduct solidifying and clogging lines) and was eventually abandoned in favor of the Siemens process.

In the Siemens process, high-purity silicon rods are exposed to trichlorosilane at 1150 °C. The trichlorosilane gas decomposes and deposits additional silicon onto the rods, enlarging them according to chemical reactions like

- 2 HSiCl3 → Si + 2 HCl + SiCl4.

Silicon produced from this and similar processes is called polycrystalline silicon. Polycrystalline silicon typically has impurity levels of less than 10−9.

In 2006 REC announced construction of a plant based on fluidized bed technology using silane [2].

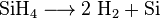

- 3SiCl4 + Si + 2H2 → 4HSiCl3

- 4HSiCl3 → 3SiCl4 + SiH4

- SiH4 → Si + 2H2

[edit] Crystallization

The majority of silicon crystals grown for device production are produced by the Czochralski process, (CZ-Si) since it is the cheapest method available and it is capable of producing large size crystals. However, silicon single-crystals grown by the Czochralski method contain impurities since the crucible which contains the melt dissolves. For certain electronic devices, particularly those required for high power applications, silicon grown by the Czochralski method is not pure enough. For these applications, float-zone silicon (FZ-Si) can be used instead. It is worth mentioning though, in contrast with CZ-Si method in which the seed is dipped into the silicon melt and the growing crystal is pulled upward, the thin seed crystal in the FZ-Si method sustains the growing crystal as well as the polysilicon rod from the bottom. As a result, it is difficult to grow large size crystals using the float-zone method. Today, all the dislocation-free silicon crystals used in semiconductor industry with diameter 300mm or larger are grown by the Czochralski method with purity level significantly improved.

[edit] Different forms of silicon

One can notice the color change in silicon nanopowder. This is caused by the quantum effects which occur in particles of nanometric dimensions. See also Potential well, Quantum dot, and Nanoparticle.

[edit] Isotopes

-

Silicon has numerous known isotopes, with mass numbers ranging from 22 to 44. 28Si (the most abundant isotope, at 92.23%), 29Si (4.67%), and 30Si (3.1%) are stable; 32Si is a radioactive isotope produced by argon decay. Its half-life has been determined to be approximately 170 years (0.21 MeV), and it decays by beta - emission to 32P (which has a 14.28 day half-life [3]) and then to 32S.

[edit] Silicon-based life

Since silicon is similar to carbon, particularly in its valency, some people have proposed the possibility of silicon-based life. One main detraction for silicon-based life is that unlike carbon, silicon does not have the tendency to form double and triple bonds.

Although there are no known forms of life that rely entirely on silicon-based chemistry, there are some that rely on silicon minerals for specific functions. Some bacteria and other forms of life, such as the protozoa radiolaria, have silicon dioxide skeletons, and the sea urchin has spines made of silicon dioxide. These forms of silicon dioxide are known as biogenic silica. Silicate bacteria use silicates in their metabolism.

Life as we know it could not have developed based on a silicon biochemistry. The main reason for this fact is that life on Earth depends on the carbon cycle: autotrophic entities use carbon dioxide to synthesize organic compounds with carbon, which is then used as food by heterotrophic entities, which produce energy and carbon dioxide from these compounds. If carbon was to be replaced with silicon, there would be a need for a silicon cycle. However, silicon dioxide precipitates in aqueous systems, and cannot be transported among living beings by common biological means.

As such, another solvent would be necessary to sustain silicon-based life forms; it would be difficult (if not impossible) to find another common compound with the unusual properties of water which make it an ideal solvent for carbon-based life. Larger silicon compounds analogous to common hydrocarbon chains (silanes) are also generally unstable owing to the larger atomic radius of silicon and the correspondingly weaker silicon-silicon bond; silanes decompose readily and often violently in the presence of oxygen making them unsuitable for an oxidizing atmosphere such as our own. Silicon also does not readily participate in pi-bonding (the second and third bonds in triple bonds and double bonds are pi-bonds) as its p-orbital electrons experience greater shielding and are less able to take on the necessary geometry. Furthermore, although some silicon rings (cyclosilanes) analogous to common the cycloalkanes formed by carbon have been synthesized, these are largely unknown. Their synthesis suffers from the difficulties inherent in producing any silane compound, whereas carbon will readily form five-, six-, and seven-membered rings by a variety of pathways (the Diels-Alder reaction is one naturally-occurring example), even in the presence of oxygen. Silicon's inability to readily form long silane chains, multiple bonds, and rings severely limits the diversity of compounds that can be synthesized from it. Under known conditions, silicon chemistry simply cannot begin to approach the diversity of organic chemistry, a crucial factor in carbon's role in biology.

However, silicon-based life could be construed as being life which exists under a computational substrate. This concept is yet to be explored in mainstream technology but receives ample coverage by sci-fi authors.

A. G. Cairns-Smith has proposed that the first living organisms to exist were forms of clay minerals—which were probably based around the silicon atom.

[edit] Compounds

For examples of silicon compounds see silicate, silane (SiH4), silicic acid (H4SiO4), silicon carbide (SiC), silicon dioxide (SiO2), silicon tetrachloride (SiCl4), silicon tetrafluoride (SiF4), and trichlorosilane (HSiCl3).

See also Category:Silicon compounds

[edit] References

- ^ [1], E.-C. Koch, D. Clement, Special Materials in Pyrotechnics: VI. Silicon - An Old Fuel with New Perspectives

- ^ http://hugin.info/136555/R/1115224/203491.pdf REC presentation to investors accessed 8 July 2007

BW Bewise Inc. Willy Chen willy@tool-tool.com bw@tool-tool.com www.tool-tool.com skype:willy_chen_bw mobile:0937-618-190 Head &Administration Office No.13,Shiang Shang 2nd St., West Chiu Taichung,Taiwan 40356 TEL:+886 4 24710048 / FAX:+886 4 2471 4839 N.Branch 5F,No.460,Fu Shin North Rd.,Taipei,Taiwan S.Branch No.24,Sec.1,Chia Pu East Rd.,Taipao City,Chiayi Hsien,Taiwan

Welcome to BW tool world! We are an experienced tool maker specialized in cutting tools. We focus on what you need and endeavor to research the best cutter to satisfy users’ demand. Our customers involve wide range of industries, like mold & die, aerospace, electronic, machinery, etc. We are professional expert in cutting field. We would like to solve every problem from you. Please feel free to contact us, its our pleasure to serve for you. BW product including: cutting tool、aerospace tool .HSS Cutting tool、Carbide end mills、Carbide cutting tool、NAS Cutting tool、Carbide end mill、Aerospace cutting tool、Фрезеры’Carbide drill、High speed steel、Milling cutter、CVDD(Chemical Vapor Deposition Diamond )’PCBN (Polycrystalline Cubic Boron Nitride) ’Core drill、Tapered end mills、CVD Diamond Tools Inserts’PCD Edge-Beveling Cutter(Golden Finger’PCD V-Cutter’PCD Wood tools’PCD Cutting tools’PCD Circular Saw Blade’PVDD End Mills’diamond tool ‘Single Crystal Diamond ‘Metric end mills、Miniature end mills、Специальные

,

,

/m·

/m·